-

Home

-

Product

-

Concentric Butterfy Valve

Concentric Butterfy Valve

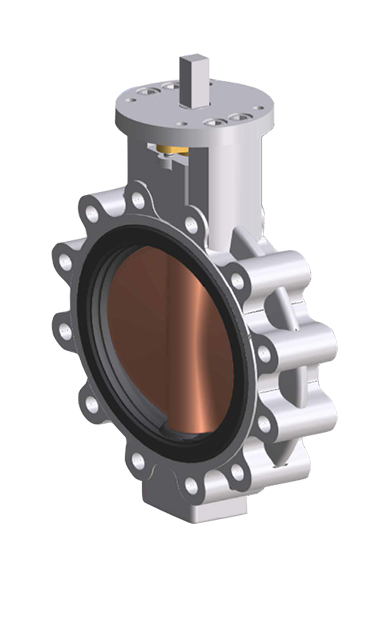

GVK-1000 SERIES

We provide products to various industries with rubber seat type butterfly valves based on perfect shielding function.

WAFER, SEMI-LUG, LUG, FLANGE

Standard Compliance

International Standard API609, JIS F7480, KSV7490, ISO5752, JIS B2032, BS5155, DIN2501.

Production Range

- SIZE : WAFER DN50 ~ DN500

LUG DN50 ~ DN800

FLANGE DN50 ~ DN1200 (other Dimensions on request) - Rating Pressure : Up to 16Barg

- Rating Temperature : -25℃ ~ 120℃

Applicable Flange Standard

- KS/JIS 5K, 10K, 16K- ASME B16.1 Class 125LB

- ASME B16.5 Class 150LB

- ISO 7005 PN6, PN10, PN16

- EN 1092 PN6, PN10, PN16

- GB 2501/2506 PN6, PN10, PN16

- DIN 2501 PN6, PN10, PN16

Operations

- Manual Lever, Worm gear operation

- Single & Double Acting Pneumatic Actuator operation

- Electric Motor Actuator operation

- Hydraulic Actuator & Manual Hydraulic Actuator operation

Material

-

Body

Cast Iron / Ductile Iron

Cast Steel

Stainless steel

Al-bronze -

Disc

Stainless steel

Al-bronze - Seat Rubber - NBR, EPDM, VITON

- Stem Stainless steel

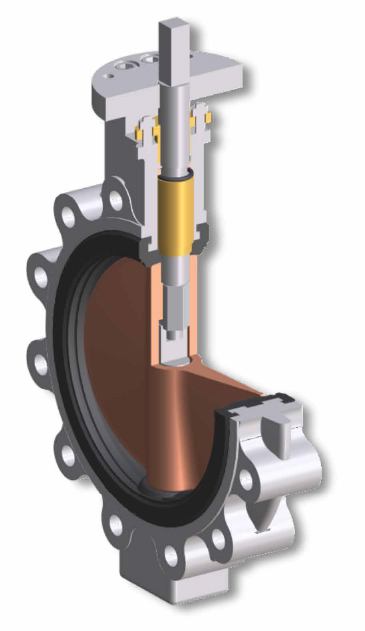

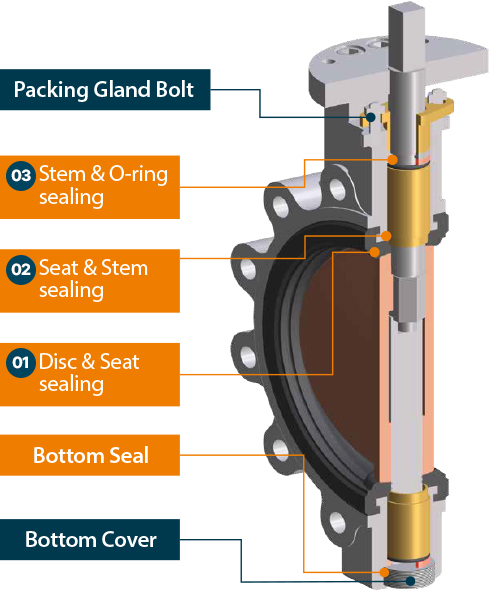

DESIGN FEATURE

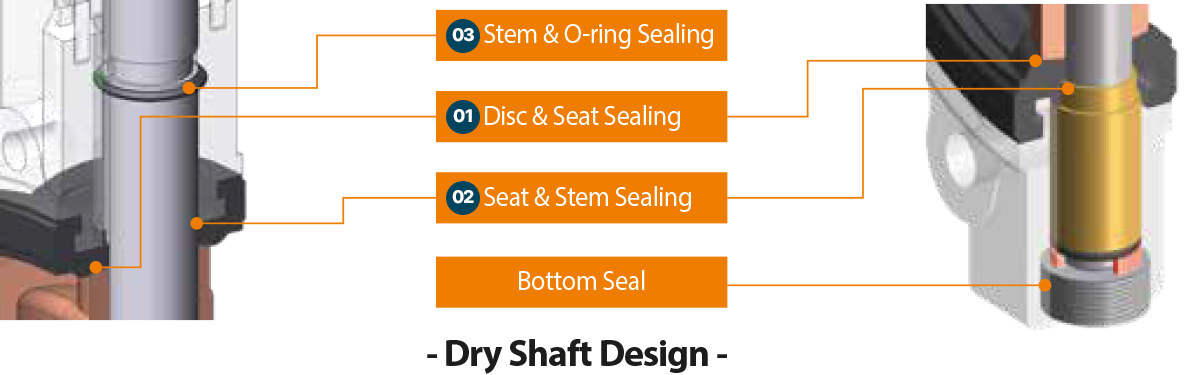

Complete dry shaft sealing design.

-

Multi seal design keeps the sealing in way of valve stem perfectly without

additional tightening device after operating of the valve.

- 01 Disc(top&down side) & seat sealing shows perfect sealing e ect with connection with the sphere shape.

- 02 Even if the disc part leaked by the uid pressure to keep the position by the seat & stem sealing part will be remained without deformation for sealing.

- 03 O-ring part exists in the valve independently of the seat to prevent leakage.

- If leaking on multi seal design in case, leakage will not occurred by tightening packing gland bolt.(Bottom cover) Because the seat connected to the stem bearings are better sealed by packing gland bolt(& bottom cover) tightening pressure and have a complete sealing structure.

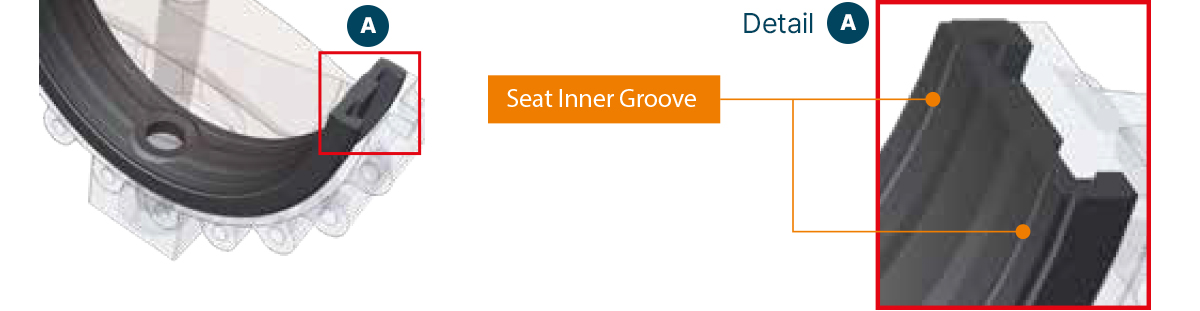

Seat Design

- GV Korea's Concentric butter y valve have a superb structure in the seat.

- The central part of the seat top&down is same spherical shape as disc so that the seat can contact the disc smoothly.

- The disc in contact with the spherical seat operates at low torque.

- The seat inner groove prevents deformation of the seat by piping tightening pressure. Also, it's possible to reduce the torque increased on the valve seat when the piping tightening pressure.

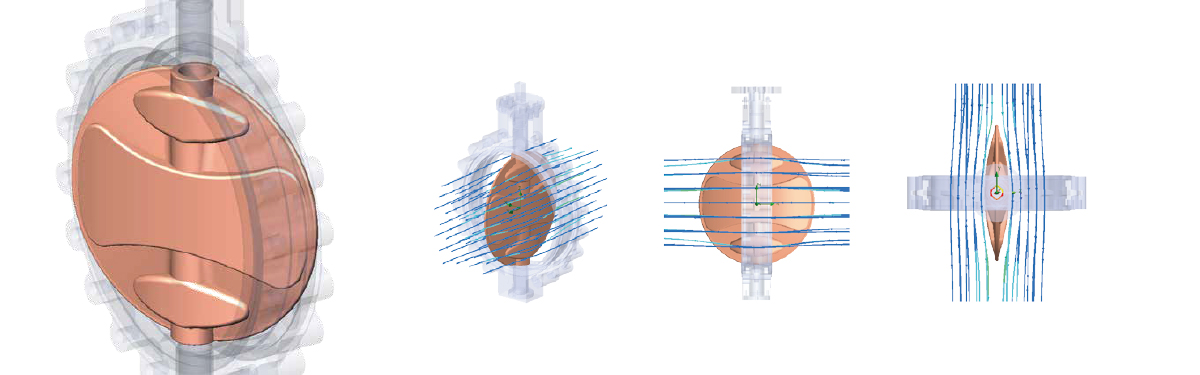

Disc Design

- Disc is designed as special structure which maintains a su cient intensity under high-pressure and high velocity.

- The disc is produced by full spherical machining.

- Every part of the sealing surface is spherical as the seat surface.

- These t together with a smooth touch and torque are reduced.

- Specially, the disc design of above DN400 is shaped to suit uid ow as shown in the gure and prevents turbulence.

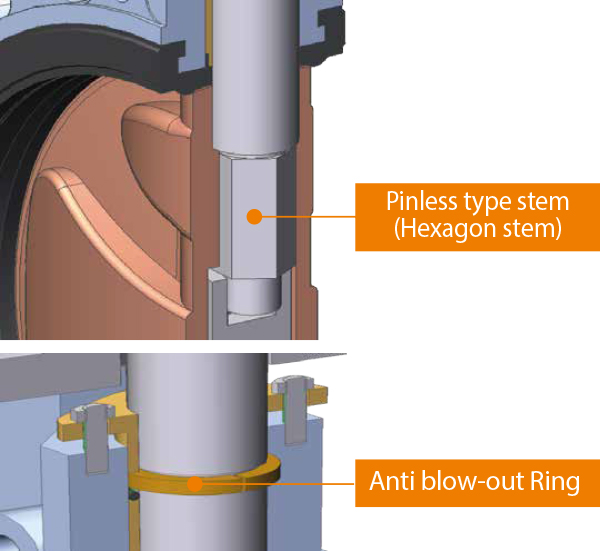

Pinless type Stem Design(Hexagon type stem)

- Pinless type stem(Hexagon type stem) to be provided to x disc into the stem, instead of thread bolt & taper type pin to avoid unexpected releasing thread of the caused by the environmental vibration and disc pin corrosion.

- It is easy to disassemble and assemble after installation, and is fully compatible without additional processing when supplying spare parts.

Blow-Out Proof Stem

- The antiblow ring is installed between the machinical stem groove and gland ring.

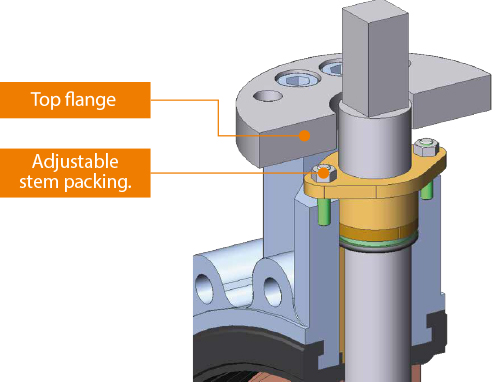

Adjustable Stem Packing.

- The O-rings and seats connected to the stem bearings are better sealing through gland bolting pressure even after the valve is installed on the pipe.

- The stem packing design features easy access to adjusting hex head nuts without special tool.

Top Flange For Actuator Mount (ISO 5211 Standard)

- It is provided in accordance with the ISO 5211 standard.

PDF Download