-

Home

-

Product

-

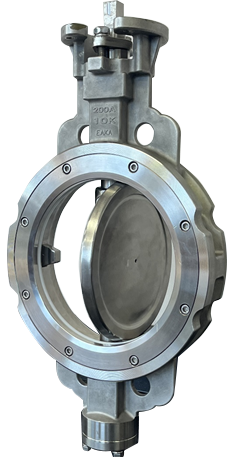

Eccentric Butterfy Valve

Eccentric Butterfy Valve

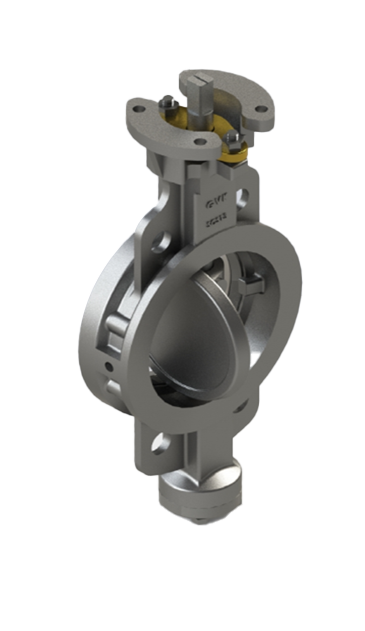

GVK-2000 SERIES

Friction Zero Double Offset Design

A new Concept of Innovative Double offset Design Valve has been successfully developed and it provides extreme high performance when compared to other type of Metal Seated Butterfly Valves including Triple.

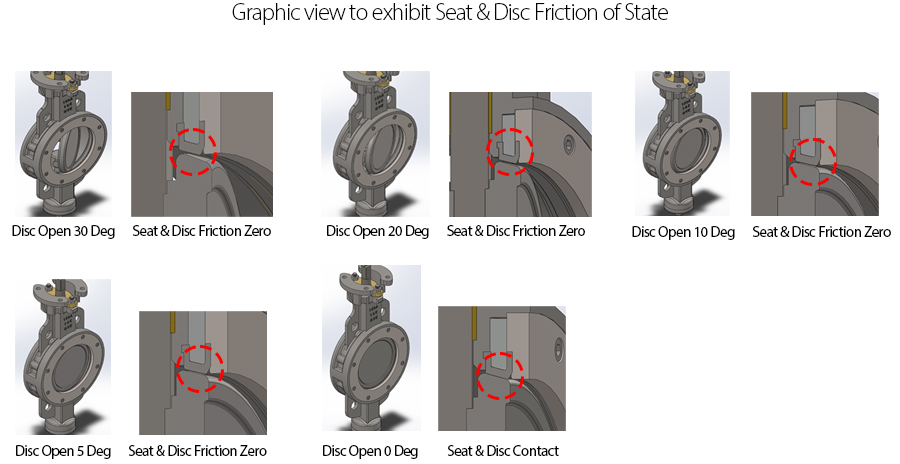

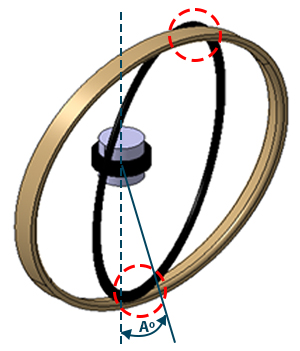

DESIGN CONCEPT

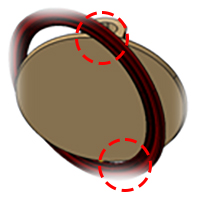

GVK 2000 Double Offset Design is Unique and the First in the world. It provides ZERO friction on overall surface of seats when both open & close of the disc during operation which leads to less torque than ever. Also, Perfect seat sealing with no seat leakage is well achieved. Therefor no friction is during operation, Which maximizes durability

Offset Design Seat & Disc Friction of State

| Division | Aº (Interference Angle) | Advantage |

|---|---|---|

| GVK 2000Series | Friction Zero. |

|

| Existing Valve | Friction occur at degree of 0º~25º. |

|

Existing Valve Offset Design

| Contact |

|

|

|

|

|---|---|---|---|---|

| Open Angle | 25° | 15° | 10° | 5° |

KEY FEATURES

- Unique and Innovative Functional Design

- Friction Zero Double offset Design

- Solid Metal to Metal Seat with hard facing as a basic trim design, Metal to Soft Seat as an option

- Replaceable Metal Seat with Retainer

KEY RESULTS

- Zero Friction for Seating when disc is either being closed or opened

- Intact Seat Face against Severe Service

- Bidirectional Tight shutoff

- No worry of seat damage compare to laminated seat of triple offset butterfly valve

KEY BENEFITS FOR CUSTOMER

- Longer Service Life

- Lower costs for Actuation by Zero Friction & Lower Operating Torque

- Cost Saving by Less Trouble

- Reliable with long-term operation

RECOMMENDED APPLICATION

- Corrosive / Erosive media service including sludge, slurry, oil sand, coal ash, waste water etc

- Severe Service including PP (Propylene Polymer in Vapor/Solid) line, Naptha Cracking line etc

- Frequent Open / Close of the line

- High temperature Service

- High Pressure Service

- Replaceable with current Triple Offset Butterfly Valve

- Replaceable with Soft Seated Valve where abrasive media flows

COMPARISON TABLE

| Description | GVK 2000 Double Offset | Other Company Double Offset |

|---|---|---|

| Offsets | Double offset | Double offset |

| Stem / Disc Operating | 90 Deg Rotaing | 90Deg Rotaing |

| Seat material | Solid metal to metal, Metal to laminated seat Metal to soft seat also available | Impossible Solid metal to metal Impossible Metal to laminated seat |

| Impacts(seat damage) the on seat against Flow | NO impacts | Impacts |

| Friction when seating on & off | Zero ftiction - by Optimizing Offset Design | Friction occur at deg of 0°~25° |

| Seat Shut off at full pressure rate for non-preferred direction | No seat Leakage under metal to metal seat | Hard to reach metal to metal |

| Bi-directional tight shut off | Available | Hard to achieve |

| Seat Surface Hard facing Treatment available | Overlay wedling [Body seat & Disc seat] TCC, CCC by HVOF | Hard to achieve |

| Parts Repair

Disc & seat replacement |

Easy & Simple to replace it on site | Easy & Simple to replace it on site |

| Actuator applicable | Pneumatic, Electric & Hydraulic with Quarter turn only | Pneumatic, Electric & Hydraulic with Quarter turn only |

| Severe Service application (wear & Tear, erosion) | Suitable with intact metal seat face, | Difficult due to non solid metalic seat |

| Severe Service application (corrosion) | Suitable with TCC, CCC on the seats | Difficult due to non solid metalic seat |

| Alternatively replaceable with Ball, Gate, Glove valve | Yes for metal seat | Few |

| Fire safe | Yes with metal to metal seat design | Yes with metal to metal & soft seat design |

DESCRIPTION

- International Standard: API609, JIS F7480, ISO5752, JISB2032, BS5155

- Applicable SIZE Range [Other sizes on request]

- Wafer DN 50 ~ DN 500

- Lug DN 50 ~ DN 800

- Flange DN 50 ~ DN 2000

- Applicable Pressure Range Class 125, 150, 300, 600

- Applicable Temperature Range: -196℃ ~ 550℃

- Applicable Flange standard:

- KS/JIS 10K, 16K, 20K, 30K

- ASME B16.5, ASME B16.1 Class 125, 150, 300, 600

- ISO 7005/EN 1092 / DIN 2501 PN6, PN10, PN16, PN25, PN40

- Operations

- Worm & Bevel Gear operation

- Pneumatic / MOV / Hydraulic ACT.