-

Home

-

R & D

-

Technology development

Technology development

Technology development1

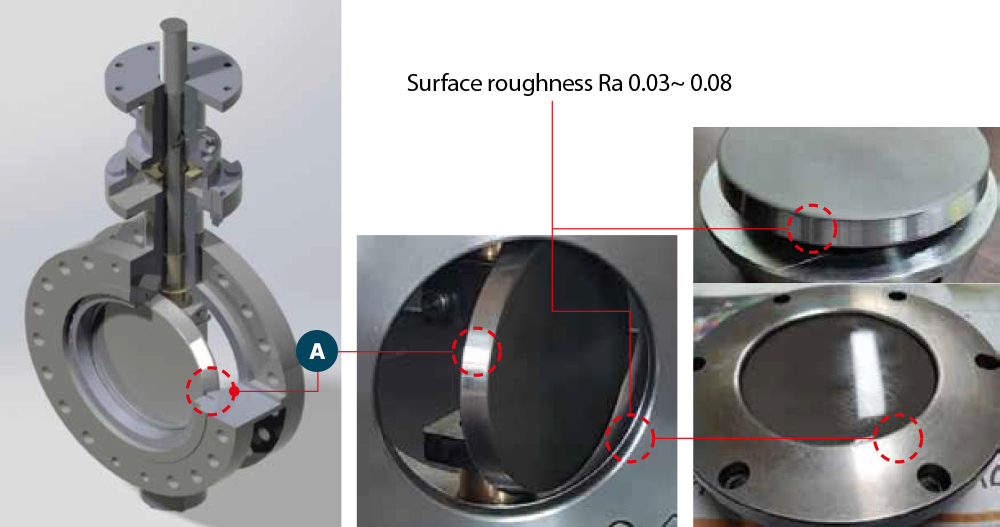

Special Coating of Disc & Metal Seat

- Disc & Sealing surface roughness TCC coating or Stelite over ray After coating, polishing and lapping treatment surface roughness Ra 0.03~0.08

-

A

Surface roughness of Disc & Seat surfaces

- Solid TCC Coating and Stellite Overlay

- Perf orm polishing and rapping after coating, and maintaining

Technology development2

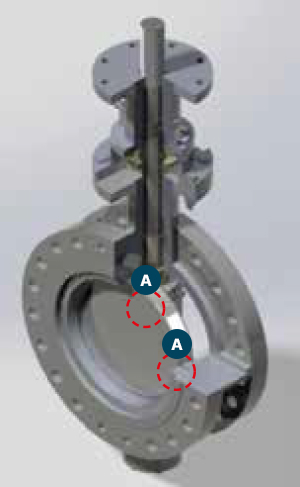

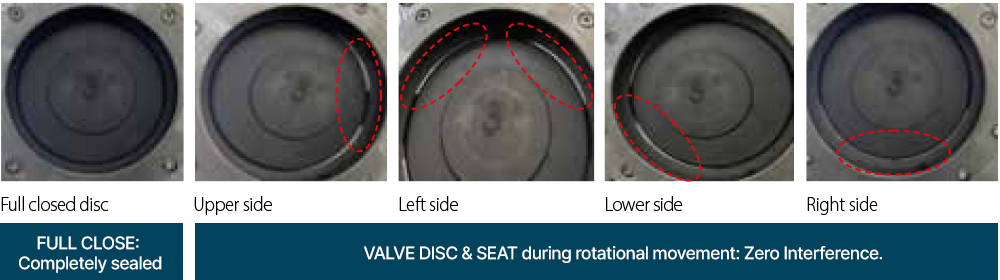

Disc & Seat surfaces zero friction

-

Friction free of seating surfaces from before disc rotating

- Interference is eliminated because valve disc moves in a linear before the Open/Close rotation and then performs with rotation acts.

-

ADisc & Seat surfaces zero friction

- Solid Metal to Metal Sealing Basically. Can be used at high pressure by realizing sealing

Technology development3

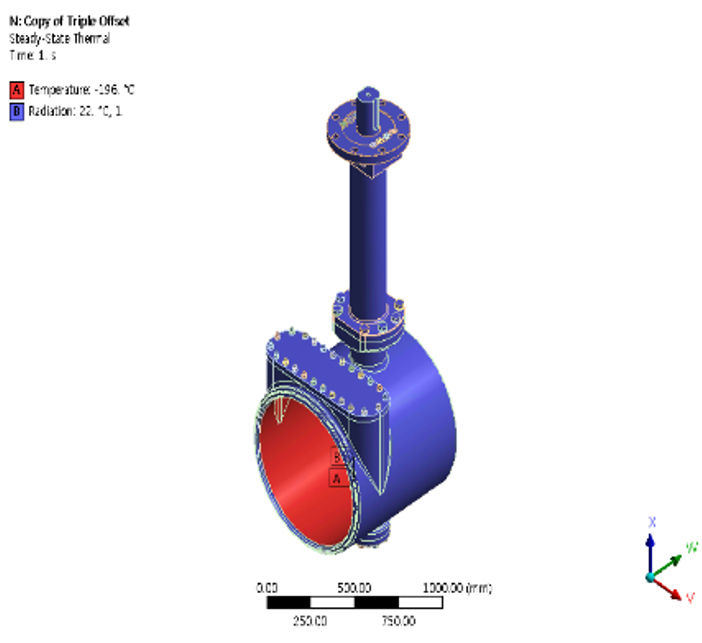

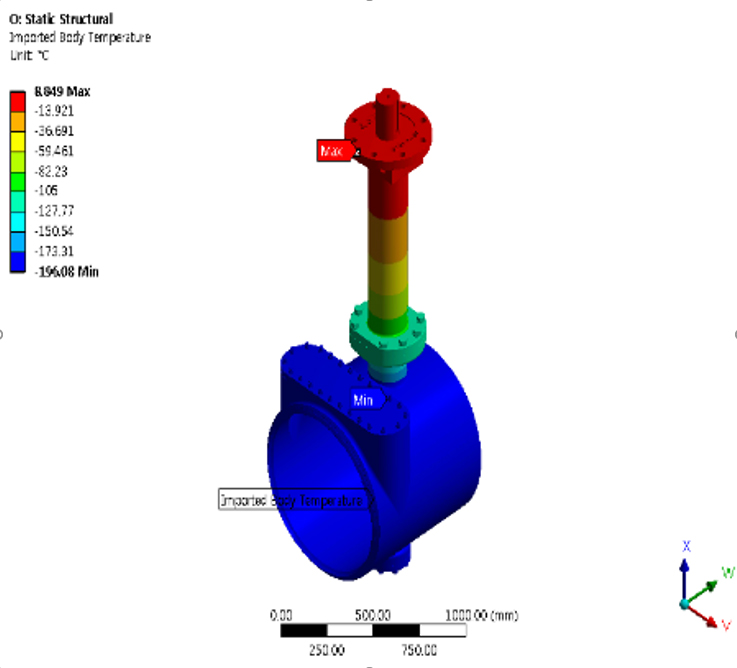

GVK-3000 SERIES CRYOGENIC ANALYSIS

- STEADY-STATE THERMAL & THERMAL STRESS ANALYSIS

-

MESH STATICS

- Nodes 829.947

- Elements 438.294

-

Results

Pipe Line : -196 ˚C

Operator : 8.8 ˚

-

BOUNDARY CONDITION 1

Radiation Condition all over the outer surface

- Environmental Temperature 22℃

- Internal Temperature -196℃

-

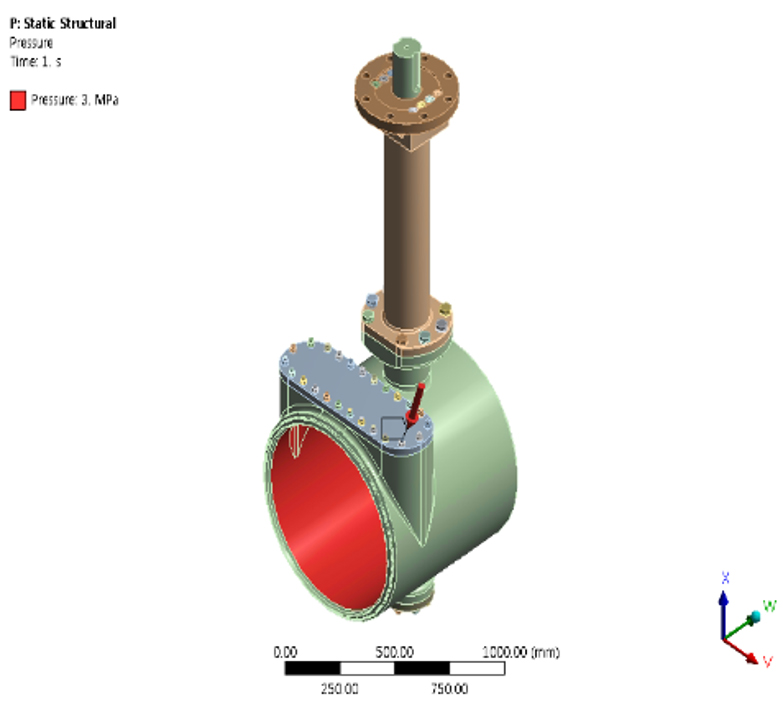

BOUNDARY CONDITION 2

- Shell Design Pressure 30bar

-

BOUNDARY CONDITION 2

- Steday-State analysis result

-

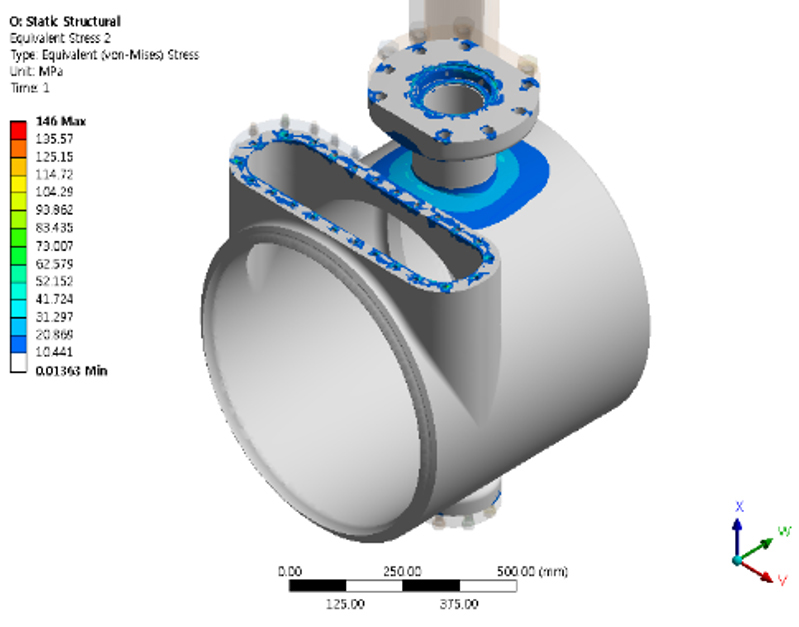

VON-MISES STRESS

- MAX. 146 MPa

-

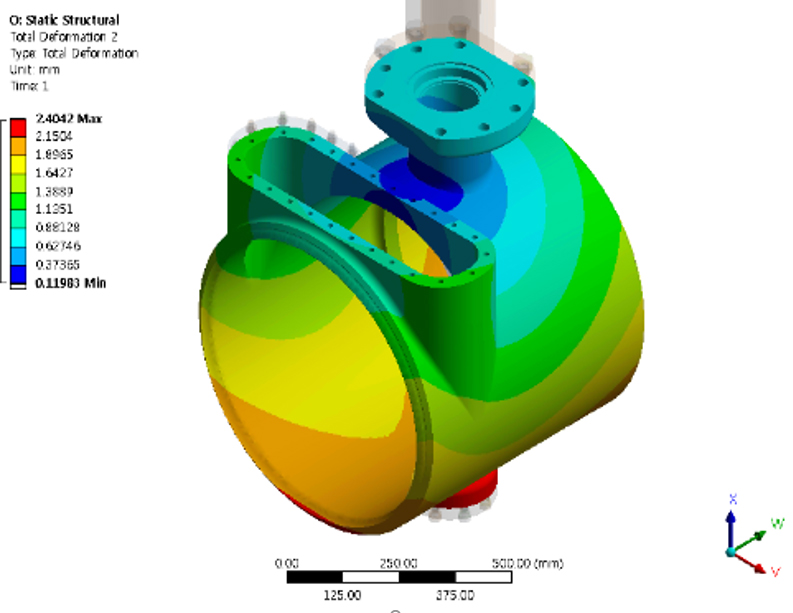

TOTAL DEFORMATION

- MAX. 1.57mm